E-WASTE MICROFACTORY REPURPOSES JUNK COMPONENTS

The University of New South Wales has launched an e-waste processing microfactory, transforming the components from electronic waste (e-waste) items such as discarded smart phones and laptops into valuable materials for re-use.

Using technology developed at UNSW’s Centre for Sustainable Materials Research and Technology (SMaRT Centre), the e-waste microfactory will do its part to reduce the rapidly growing problem of electronic waste causing environmental harm and going into landfill.

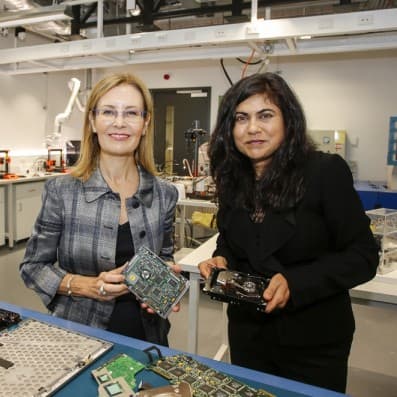

At the microfactory launch, NSW Minister for the Environment Gabrielle Upton said it was exciting to see technological innovations that could transform waste management and recycling.

“I am very pleased to launch the UNSW e-waste microfactory today, a NSW home-grown solution to the waste challenges facing communities all over the world,” Minister Upton said.

“It is exciting to see innovations such as this prototype microfactory and the potential they have to reduce waste and provide a boost to both the waste management and manufacturing industries in NSW.”

SMaRT Centre Director, Professor Veena Sahajwalla, said the e-waste microfactory was the first of a series of microfactories under development and in testing at UNSW that can also turn many types of consumer waste such as glass, plastic and timber into commercial materials and products.

For instance, from e-waste, computer circuit boards can be transformed into valuable metal alloys such as copper and tin while glass and plastic from e-devices can be converted into micromaterials used in industrial grade ceramics and plastic filaments for 3D printing.

“Using our green manufacturing technologies, these microfactories can transform waste where it is stockpiled and created, enabling local businesses and communities to not only tackle local waste problems but to develop a commercial opportunity from the valuable materials that are created.”

Prof Sahajwalla said microfactories presented a solution to burning and burying waste items that contain materials which can be transformed into value-added substances and products to meet existing and new industry and consumer demands.

“We have proven you can transform just about anything at the micro-level and transform waste streams into value-added products. For example, instead of looking at plastics as just a nuisance, we’ve shown scientifically that you can generate materials from that waste stream to create smart filaments for 3D printing,” she said.

While the SMaRT Centre is expanding its partnerships with industry, investors and local councils, the challenge is to commercialise and create incentives for industry to take up this technology – and to change behaviour – as societies and communities around the world seek to be more sustainable.