WASTE HEAT TO POWER MILLIONS OF HOMES?

Researchers at Yale have developed a new technology that could make energy from the low-temperature wasted heat produced by industrial sources and power plants.

It's an idea that makes you go "Why on earth didn't I think of that?", and it's almost surprising it hasn't been done before. Waste heat is everywhere, and by definition, is almost completely untapped.

Initial estimates indicate that recoverable waste heat in the U.S. alone could power tens of millions of homes.

Although existing technologies can reuse high-temperature heat or convert it to electricity, it is difficult to efficiently extract energy from low-temperature heat waste due to the small temperature difference between the plant’s heat discharge and the surrounding environment.

Additionally, conventional systems are designed to target a specific temperature difference, so they’re less effective when there are fluctuations in the output of waste heat.

Researchers at Yale’s Department of Chemical and Environmental Engineering have found that the key is a “nanobubble membrane” that traps tiny air bubbles within its pores when immersed in water.

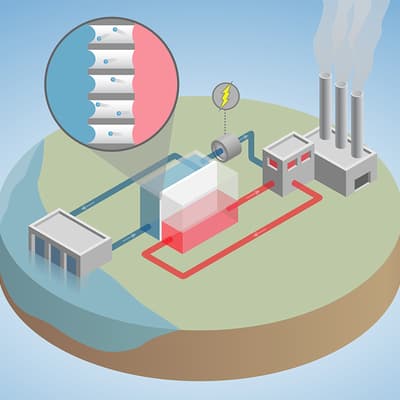

Heating one side of the membrane causes water to evaporate, travel across the air gap, and condense on the opposite side of the membrane. This temperature-driven flow of water across the membrane is then directed to a turbine to generate electricity: a micro-scale steam turbine.

To prove the concept, the team built a small-scale system and demonstrated that the nanobubble membranes could produce pressurized flows of water and generate power even with heat fluctuations and temperature differences as small as 20 degrees Celsius — making it feasible for use with the wasted heat from industrial sources.

The findings were published online June 27 in the journal Nature Energy.